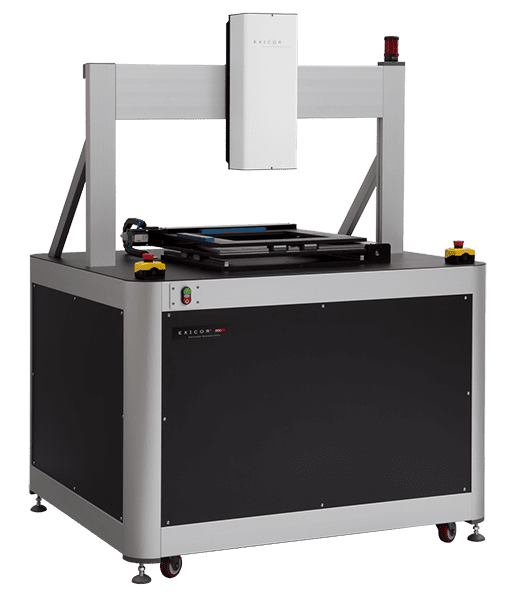

Exicor® AT Series

Exicor® AT Series

The AT Series is the original member of the Exicor birefringence measurement system family of products. It also includes the workhorse model, serving both R&D and production requirements.

Benefits of the Exicor® AT

- The standard high speed scanning package, Scan in Motion™ or SIM, makes high spatial resolution scans (<1 mm grid spacing) practical.

- Unprecedented sensitivity in low-level birefringence measurement

- Simultaneous measurement of birefringence magnitude and angle

- Precision repeatability

- High-speed measurement

- Automatic mapping of variable-sized optical elements

Intuitive Operation

Simple, user-friendly operation guided by software. Become more efficient with your testing, data gathering, and information analysis.

No Moving Optics

Increased consistency during measuring because you’re not constantly having to readjust stage, materials, or other variables.

Small Applications

Ideal for use on plastic films, lens blanks, laser crystals, cell phone display windows, and other intricate materials.

Available Models

Exicor® 120AT |

Exicor® 150AT |

Exicor® 250AT |

Exicor® 300AT |

Exicor® 500AT |

|

| System Size: | 715mm (H) x 350mm (W) x 360mm (D) | 413mm (W) x 693mm (D) x 909mm (H) | 910mm (H) x 415mm (W) x 700mm (D) | 120cm (L) x 130cm (W) x 200cm (H) | 150cm (L) x 150cm (W) x 200cm (H) |

| Max. Sample Size: | up to 120mm x 100mm | up to 150mm x 150mm | up to 250mm x 250mm | up to 300mm x 300mm and 250+mm thick | up to 500mm X 500mm and 400+mm thick |

System Details

Custom configurations and accessories are available for these models. Please contact a representative for more details.

Features

Features of 120AT, 150AT & 250AT Models

- Automated XY stage

- 2D and 3D graphical representation of birefringence parameters

- Bench top design

- Flexible stage design for adding custom parts holders or process aids

- Advanced data analysis features included standard in user interface

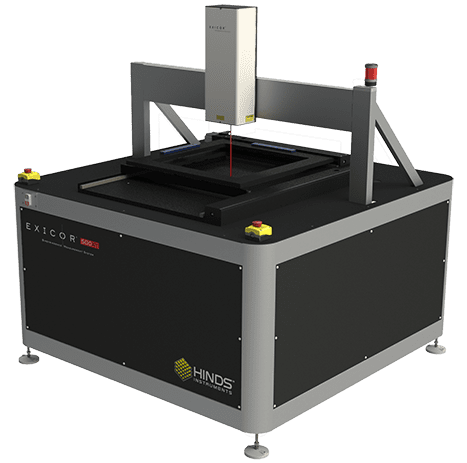

Features of 300AT & 500AT Models

- Heavy duty automated XY stage

- 2D and 3D graphical representation of birefringence parameters

- 3-sided easy access stage loading design

- Large and flexible stage platform design for adding custom parts holders or process aids

- Advanced data analysis features included standard in user interface

Specifications

| 120AT | All Other AT Models | |

| Retardation Range: | 0.005 to 300+ nm | 0.005 to 300+ nm |

| Retardation Resolution / Repeatability1, 2: | 0.001 nm / ± 0.02 nm | 0.001 nm / ± 0.015 nm |

| Angular Resolution / Repeatability1: | 0.01º / ± 0.07° | 0.01º / ± 0.07° |

| Measurement Rate / Time3: | 15 samples/sec (at 1nm spacing) | up to 100 pps / sample size dependent |

| Light Source Wavelength4: | Various (625nm standard) | Various (632.8 nm standard) |

| Measurement Spot Diameter5: | Between 1 mm and 3 mm (can be as low as <50 µm) | Between 1 mm and 3 mm (can be as low as <50 µm) |

| Modulation Technique / Frequency: | PEMLabsTM Photoelastic Modulator / 50 kHz and 50/60 kHz | PEMLabsTM Photoelastic Modulator / 50 kHz and 50/60 kHz |

| Demodulation Analysis Technique: | Hinds Instruments SignalocTM Lock-in Amplifier | Hinds Instruments SignalocTM Lock-in Amplifier |

| Measurement Units: | nm (retardation), ° (angle) | nm (retardation), ° (angle) |

- 1 Typical performance at 5nm retardation

- 2 Up to 1.5 nm, 1% thereafter

- 3 Maximum data collection speed. Sample XY scan time dependent on stage movement parameters.

- 4 Custom wavelengths available

- 5 Measurement spot sizes of less than 1mm (native) require optional high resolution detector module

Resources

Techniques

Further Reading

- Birefringence and piezo-Raman analysis of single crystal CVD diamond and effects on Raman laser performance, Hadiya Jasbeer, Robert J. Williams, Ondrej Kitzler, Aaron McKay, Soumya Sarang, Jipeng Lin, and Richard P. Mildren, OSA Publishing, JOSA B, Vol. 33, Issue 3, Page B56 (2016)

- Birefringence characterization of injection molded microplates, Achyut Adhikari, Anand Asundi, Proceedings Volume 9302, International Conference on Experimental Mechanics 2014; 93022Q (2015)

- Birefringent properties of cyclic block copolymers and low-retardation-film development, Weijun Zhou, Charles Diehl, Dan Murray, Kurt A. Koppi, Stephen Hahn, Shin-Tson Wu, Journal of the SID, 18/1, 2010

Worldwide Offices

Africa

Hinds Instruments, Inc.

7245 NE Evergreen Pkwy

Hillsboro, OR 97124

USA

Phone: 1.503.690.2000

Fax: 1.503.690.3000

Email: sales@hindsinstruments.com

Americas

Hinds Instruments, Inc.

7245 NE Evergreen Pkwy

Hillsboro, OR 97124

USA

Phone: 1.503.690.2000

Fax: 1.503.690.3000

Email: sales@hindsinstruments.com

India

Hinds Instruments, Inc.

7245 NE Evergreen Pkwy

Hillsboro, OR 97124

USA

Phone: 1.503.690.2000

Fax: 1.503.690.3000

Email: sales@hindsinstruments.com

Japan

Tokyo Instruments Inc.

Attn: Mr. Toshihiko Masuda

T.I.Building,

6-18-14 Nishikasai Edogawa-Ku,

Tokyo 134-0088

JAPAN

Phone: +81 3 (3686) 4711

Fax: +81 3 (3686) 0831

Email: sales@tokyoinst.co.jp

Website: https://www.tokyoinst.co.jp

PR China (Integrated Components)

Aunion Tech Co Ltd – China HQ

Attn: Jinlong Wu

3rd Floor, Building 6,

2007 Hongmei Road,

Xuhui District, Shanghai, 200233 P.R. China

Phone: +86-21-51083793

Fax: +86-21-34241962

URL: www.auniontech.com

Aunion Tech Co Ltd – Shenzhen Branch

Attn: Mary Ma

Phone: 182-2167-2726

Email: lili-ma@auniontech.com

URL: www.auniontech.com

Aunion Tech Co Ltd – Beijing Branch

Attn: Allen Tian

Phone: 185-0166-2513

Email: jinquan-tian@auniontech.com

URL: www.auniontech.com

Aunion Tech Co Ltd – Wuhan Branch

Attn: William Zhao

Phone: 130-5208-0953

Email: Weiliang-Zhao@auniontech.com

URL: www.auniontech.com

Aunion Tech Co Ltd – Xi’an Branch

Attn: Jian Wang

Phone: 180-864-6606

Email: jian-wang @auniontech.com

URL: www.auniontech.com

Aunion Tech Co Ltd – Chengdu Branch

Attn: Yi Liu

Phone: 185-1625-1865

Email: yi-liu@auniontech.com

URL: www.auniontech.com

OPCrown Photonics Co Ltd – Beijing HQ

12B18, Changyin Bdg, No. 88 Yongding Rd

Haidian District, Beijing, P.R. China, 100039

Phone: 010-68214292

Fax: 010-68214191

Email: sales@opcrown.com

Attn: Rose Zhong

Phone 131 6171 4851

EMail: rose.zhong@opcrown.com

URL: www.opcrown.com

OPCrown Photonics Co Ltd – Wuhan Branch

Attn: Paul Liu

Phone: 137 9705 5601

Email: paul.liu@opcrown.com

OPCrown Photonics Co Ltd – Su Zhou Office

Attn: Sharon Ji

Phone: 188 6212 1645

Email: sharon.ji@opcrown.com

OPCrown Photonics Co Ltd – Chengdu Office

Attn: Bryan Zhang

Phone: 185 8378 9679

Email: bryan.zhang@opcrown.com

OPCrown Photonics Co Ltd – Shenzhen Branch

Attn: Nick Yuan

Phone: 136 3160 6196

Email: nick.yuan@opcrown.com

PR China (Research Components)

Aunion Tech Co Ltd – China HQ

Attn: Jinlong Wu

3rd Floor, Building 6,

2007 Hongmei Road,

Xuhui District, Shanghai, 200233 P.R. China

Phone: +86-21-51083793

Fax: +86-21-34241962

Website: https://www.auniontech.com/

South Korea

Opto Mechanical Associates (OMA) Co.

405-11,

Goong-dong,

Yusung-gu Daejeon 305 335

KOREA

Phone: +82 42 822 9501-3

Fax: +82 42 822 9504

Email: mail@omacom.co.kr

Website: https://www.omacom.co.kr

Taiwan (Integrated Components)

Aunion Tech Co Ltd

Attn: Jinlong Wu

Rm. 905, F Building,

Everbright Convention and Exhibition Center,

No. 86 Caobao Road, Shanghai 200235 P.R. China

Phone: +86-21-51083793

Fax: +86-21-34241962

Email: jinlong-wu@auniontech.com

URL: www.auniontech.com

OPCrown Photonics Co Ltd

Room 318, East 11th Bldg, No. 83 Fuxing Rd

Haidian District, Beijing, P.R. China, 100039

Phone: 010-68214292

Fax: 010-68214191

Email: sales@opcrown.com

URL: www.opcrown.com

Taiwan (Research Components)

Aunion Tech Co Ltd

Attn: Jinlong Wu

Rm. 905, F Building,

Everbright Convention and Exhibition Center,

No. 86 Caobao Road, Shanghai 200235 P.R. China

Phone: +86-21-51083793

Fax: +86-21-34241962

Email: jinlong-wu@auniontech.com

Website: https://www.auniontech.com/

Australia

Hinds Instruments, Inc.

7245 NE Evergreen Pkwy

Hillsboro, OR 97124

USA

Phone: 1.503.690.2000

Fax: 1.503.690.3000

Email: sales@hindsinstruments.com

Austria

Acal BFi Germany GmbH

Oppelner Straße 5

82194 Gröbenzell

GERMANY

Contact: Robert Kardinal

Phone: +49 (0) 8142 6520 119

Fax: +49 (0) 8142 6520 190

Email: robert.kardinal@acalbfi.de

Website: http://www.acalbfi.de/photonics

Belarus (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: http://www.spectropol.pl/

Czech Republic (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl

Denmark

Acal BFi Nordic AB (Denmark)

Jernbanegade 23 B

DK-4000 Roskilde

DENMARK

Phone: +45 (0) 7026 2225

Fax: +45 (0) 7026 2221

Email: info@acalbfi.dk

Website: https://www.acalbfi.com/se

Estonia (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl

Finland

Acal BFi Nordic AB (Finland)

Teknobulevardi 3-5

FI-01530 Vantaa

FINLAND

Phone: +358 (0) 207 969 770

Fax: +358 (0) 207 969 771

Email: info@acalbfi.fi

Website: https://www.acalbfi.com/se

France

Acal BFi France SAS

1 allée de la Chartreuse

91080 Evry-Courcouronnes

FRANCE

Contact: Jocelyn TANAÏS

Phone: +33 (0) 1 60 79 59 06

Fax: +33 (0) 1 60 79 89 01

Email: photonique.fr@acalbfi.fr

Website: https://www.acalbfi.com/fr

Germany

Acal BFi Germany GmbH

Oppelner Straße 5

82194 Gröbenzell

GERMANY

Contact: Robert Kardinal

Phone: +49 (0) 8142 6520 119

Fax: +49 (0) 8142 6520 190

Email: robert.kardinal@acalbfi.de

Website: https://www.acalbfi.com/de

Ireland

Acal BFi UK Limited

Room 1.09

Challenge House

Sherwood Drive

Bletchley

Milton Keynes

MK3 6DP

UNITED KINGDOM

Phone: +44 (0) 1189 788 878

Fax: +44 (0) 1908 221 110

Email: sales-uk@acalbfi.co.uk

URL: www.acalbfi.com/uk

Acal BFi UK Limited

3 The Business Centre

Molly Millars Lane

Wokingham

Berkshire

RG41 2EY

UNITED KINGDOM

Phone: +44 (0) 1189 788 878

Fax: +44 (0) 1189 776 095

Email: sales-uk@acalbfi.co.uk

URL: www.acalbfi.com/uk

Italy

Acal BFi Italy S.r.I.

Via Cascina Venina n.20

20090 Assago

Milan

ITALY

Phone: +39 (02) 53583.1

Fax: +39 (02) 53583201

Email: sales-it@acalbfi.it

URL: www.acalbfi.com

Laser Optronic SRL

Via Bernardo Quaranta, 57

20139 Milano (MI)

ITALY

Phone: +39 (02) 574651

Fax: +39 (02) 57410127

Email: lop@laseroptronic.it

Latvia (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl/

Lithuania (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl/

Norway

Acal BFi Nordic AB (Norway)

PO Box 74

3529 Ryse

NORWAY

Phone: +47 3216 2060

Fax: +47 3216 2069

Email: info@acalbfi.no

Website: https://www.acalbfi.com/se

Poland (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl

Slovakia (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl

Sweden

Acal BFi Nordic AB (Sweden)

Falhagsleden 59

PO Box 1335

SE-751 43 Uppsala

SWEDEN

Phone: +46 (0) 1856 5830

Fax: +46 (0) 1869 6666

Email: info@acalbfi.se

Website: https://www.acalbfi.com/se

Switzerland

GMP SA

Avenue des Baumettes 17

CH – 1020 Renes

Phone: +41 21 633 21 21

Fax: +41 21 633 21 29

Email: info@gmp.ch

Website: https://www.gmp.ch

The Netherlands

Alphen aan den Rijn

Acal BFi Netherlands BV

J.P. Thijsseweg 1e

2408 ER Alphen aan den Rijn

THE NETHERLANDS

Phone: +31 (0) 1 7244 6060

Fax: +31 (0) 1 7244 3414

Email: sales-nl@acalbfi.nl

URL: www.acalbfi.com/nl

Eindhoven

Acal BFi Netherlands BV

Luchthavenweg 53

5657 EA Eindhoven

THE NETHERLANDS

Phone: +31 (0) 4 0250 7400

Fax: +31 (0) 4 0250 7409

Email: sales-nl@acalbfi.nl

URL: www.acalbfi.com/nl

Ukraine (Research Components)

SPECTROPOL

ul. Trakt Lubelski 271 G

04-667 Warszawa

POLAND

Phone: +48 22 617 67 17

Fax: +48 22 617 67 97

Email: biuro@spectropol.pl

Website: https://www.spectropol.pl

United Kingdom

Pro-Lite Technology Limited

Innovation Centre, University Way

Cranfield, MK43 0BT, UK

Contact: Preetesh Mistry

Phone: +44 (0)1234 436110

Email: preetesh.mistry@pro-lite.co.uk

Website: www.pro-lite.co.uk

Milton Keynes

Acal BFi UK Limited

Room 1.09

Challenge House

Sherwood Drive

Bletchley

Milton Keynes

MK3 6DP

UNITED KINGDOM

Phone: +44 (0) 1189 788 878

Fax: +44 (0) 1908 221 110

Email: sales-uk@acalbfi.co.uk

URL: www.acalbfi.com/uk

Wokingham

Acal BFi UK Limited

3 The Business Centre

Molly Millars Lane

Wokingham

Berkshire

RG41 2EY

UNITED KINGDOM

Phone: +44 (0) 1189 788 878

Fax: +44 (0) 1189 776 095

Email: sales-uk@acalbfi.co.uk

URL: www.acalbfi.com/uk

Middle East

Hinds Instruments, Inc.

7245 NE Evergreen Pkwy

Hillsboro, OR 97124

USA

Phone: 1.503.690.2000

Fax: 1.503.690.3000

Email: sales@hindsinstruments.com

Get A Quote for Systems & Components

Working together, we can discuss the suitability of our technology for your application, including a custom configuration of our base systems if needed.

Featured Article

Fundamentals, Advances, and Artifacts in Circularly Polarized Luminescence (CPL) Spectroscopy

A practical guide to CPL spectroscopy, key to future promising applications.

Upcoming Event

SPIE Photonics West 2025

The leading global conference and marketplace for lasers, biomedical optics, quantum, biophotonics technologies, optoelectronics, microfabrication, displays, and more.

Hinds Instruments © 2025. All Rights Reserved. Built with ♥ by Webfor